DCG Systems® today announced the release of the Meridian M™ system for isolation of routine and challenging electrical faults at the wafer level. Offering photon emission for transistor-level defects and leakage, and a complete portfolio of static laser stimulation techniques for metallization defects, the Meridian M system is a critical tool to support production use cases in memory and foundry failure analysis (FA) labs. Its high sensitivity, extended-wavelength DBX™ optics capture even the most challenging faults, including:

|

|

|

|

|

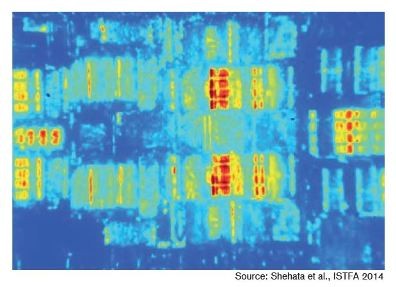

The Meridian M system also captures electrical faults that emit photons primarily in the thermal range (>1850nm), such as partial opens, high-ohmic shorts and electromigration.

“Static optical fault isolation (OFI) is in a renaissance,” said Praveen Vedagarbha, Ph.D., business unit manager of the Meridian product group at DCG Systems. “While dynamic OFI is important for localizing parametric faults, static OFI is faster and easier to use than its dynamic counterpart because it does not require docking to a tester or having the device and tester knowledge necessary to edit the test program. The speed and ease of use of the Meridian M system are particularly valuable in early yield ramp, when rapid feedback to the process engineering team is critical. ”

Among static-only optical fault isolation systems, Meridian M has demonstrated superior performance in localizing faults with the weakest photon emission. Custom-designed optics, a set of user-selectable wavelength ranges, and the lowest background noise in the industry allow Meridian M to be optimized for a variety of fault types, from conventional “optical” emitters such as excessive leakage, saturation and latch-up faults to longer-wavelength “thermal” emitters, such as high-resistance shorts and dopant displacement errors. Because it accommodates full wafers in addition to packaged die, the Meridian M system allows comparison of good die to bad die, aiding interpretation of complex thermal and photon emission images.

The Meridian product line at DCG Systems leads the industry in active installed base, with wafer-based or packaged-part systems at all leading fabless, foundry and integrated device manufacturers (IDMs). For more information about the Meridian M system, please visit the Meridian M product page.

About DCG Systems

DCG Systems, Inc. is the industry’s leading supplier of electrical fault characterization, localization and editing equipment, serving process development, yield ramp and failure analysis applications for a wide range of semiconductor and electronics manufacturers (see Top Failure Analysis System Suppliers to the Semiconductor Industry). With more than 1500 systems deployed worldwide, DCG Systems serves customers worldwide from its headquarters in Fremont, California and field offices in the United States, Japan, Taiwan, Korea, Malaysia, Singapore, Israel and Germany. For more information about DCG Systems, visit www.dcgsystems.com.