Spirox MA6503D is a high quality image wafer inspection system with features of auto-storing defects image and position coordinate records to replace QC visual inspection on surface defects, including particles, scratches, etc.

|

MA6503D

|

|

|---|---|

|

Function

|

|

|

Wafer

|

|

|

Wafer Handling

|

|

|

Chuck

|

|

|

Optical

|

|

|

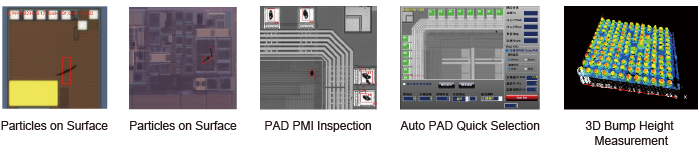

2D Image

Inspection

|

|

|

3D Image

Inspection

|

|

|

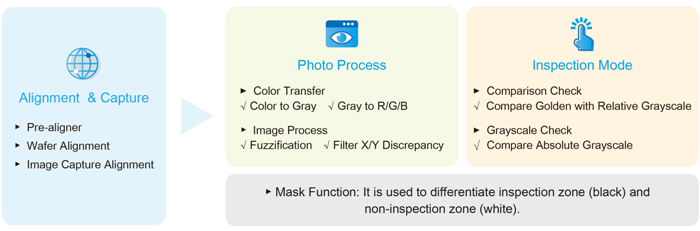

Software

|

|

|

Optional

|

|