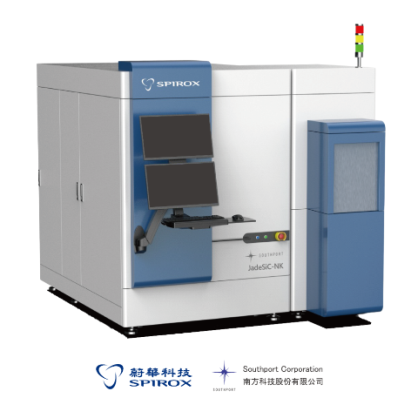

Professional semiconductor equipment provider Spirox Corporation (TWSE: 3055) has made significant strides in the field of optical inspection since the launch of its non-destructive SiC defect inspection system in November 2023, which garnered widespread acclaim in the market. Aiming to maximize the effectiveness of product services and assist customers in gaining a competitive edge in the current booming markets of compound semiconductors, power semiconductors, and Micro LED, Spirox will showcase at the Electronic Equipment Exhibition (booth number N214) from April 24th to April 26th, featuring optical inspection systems from Southport Corporation, a subsidiary of Spirox, as well as value-added IC testing equipment and maintenance services.

Paul Yang, CEO of Spirox, says "In the tide of sustainability and environmental protection, compound semiconductors with high power and high voltage characteristics has become the mainstream in global energy and electric vehicle industries. The quality and price of silicon carbide substrates, critical factors determining the manufacturing of components and the quality of module production, are the core driving force behind industry development. There is even a saying in the market that 'Who owns silicon carbide substrates will conquer the world.' Spirox focuses on the market demand of SiC substrates, and jointly unveiled the industry-first JadeSiC-NK non-destructive defect inspection system with Southport. JadeSiC-NK helps SiC substrate manufacturers save production costs, accelerate process and yield optimization. Spirox has conducted verification with numerous worldwide leading manufacturers and continuously optomizes products and services based on customer feedback. At this exhibition, Spirox advocates the idea of 100% inspection of SiC substrates. By providing inspection reports with the shipment of each substrate, we can assist customers in ensuring product quality and maintaining market prices. Additionally, this practice can drive the establishment of industry standards, facilitating the transformation of silicon carbide substrate trading models, and stabilizing the commercial development of silicon carbide substrates."

Spirox, allocated in the Compound Semiconductor Area for the first time, showcases not only the latest technological advancements of JadeSiC-NK but also introduces the JadeSA-WBG MicroArea 3D stress inspection and analysis system, which effectively reflects the inherent characteristics of wide bandgap materials. JadeSA-WBG is suitable for stress and crystal type control in SiC substrates, homoepitaxy, heteroepitaxy, and device process materials. Furthermore, Spirox extends its development efforts to epitaxial processes with JadeSiC-EPi, a system designed to detects killer defects on epitaxial layers through optical scanning, which traces the causes of defect generation and providing clear directions for process improvement. Collaborating with Southport, Spirox not only applies non-linear optical technology to compound semiconductor inspection but also expands into other popular applications such as the JadeML which is suitable for high-volume PL and non-contact high-volume leakage detection in Micro LED wafers. In the future, Spirox and Southport plan to accelerate the development of innovative optical inspection technologies such as hypermaterial and silicon photonics.

In addition, Spirox's display of testing equipment is also quite remarkable. To meet the diverse testing needs of power semiconductors, RF IC, SoC, Spirox has integrated leading vendors of automated testing and measurement equipment such as NI, the leading handler brand Osai, and Spirox’s own products to launch a series of efficient and precise testing equipment and board repair services. In terms of power semiconductor testing, Osai's power module test classification machine offers high automation and flexibility, capable of expanding testing performance for different testing environments and requirements. When combined with CREA's testing solutions, it can better meet the demand for Known Good Die (KGD) testing requirements and trends, assisting customers in producing high-quality and highly reliable products to seize market opportunities.

In response to the high integration and complex characteristics of RF and SoC chips, NI semiconductor testing systems can comprehensively test the transmission properties of RF signals and ensure the stability of chips in various application scenarios. Meanwhile, Spirox's SP2500 tester features high efficiency and throughput, enabling rapid completion of large-scale testing tasks for SoC chips and enhancing product testing and production efficiency.

With the continuous advancement of semiconductor technology and the expansion of application scope, Spirox will continue to strengthen its research and development efforts in optical inspection and chip testing and will continuously introduce more advanced and efficient testing equipment and solutions, providing customers with comprehensive and reliable technical support and services. Looking forward to engaging in in-depth discussions with customers and industry experts at the Electronic Equipment Exhibition from April 24th to April 26th (booth number N214), to jointly explore the development trends and application prospects of semiconductor equipment, and promote the sustainable development and continuous innovation of the industry.

About Spirox

Spirox Corporation (TWSE: 3055) is a professional semiconductor testing solution provider. Partnered with worldwide leading suppliers, including NI, Osai, SEMICS, AFORE, ERS, Hamamatsu, ShibaSoku, Southport, TASMIT, TESCAN, Toray Engineering, Turbodynamics, etc., Spirox provides various integrated solutions to fulfill customer needs in testing, packaging, and inspection in semiconductor industry. Founded in 1987, Spirox is headquartered in Hsinchu, Taiwan, with additional service branches in Taipei, Kaohsiung, Shanghai, Suzhou, Shenzhen and Chengdu. For more information, please visit www.spirox.com.