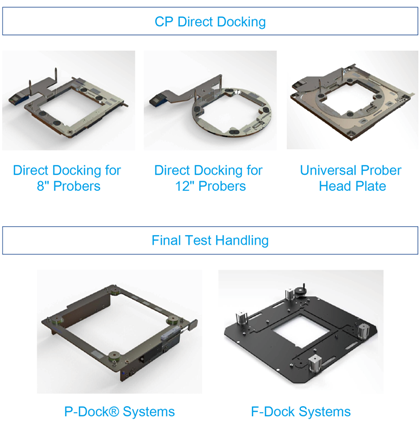

Turbodynamics' Direct Docking Systems solve three major problems of Automatic Test Equipment: poor signal performance, lack of space in production and high costs for new equipment.

Direct Docking is maintenance-free and available for all existing systems of 8'' and 12'' Probers and offers enormous advantages over OEM-based solutions, especially in the TriTemp area.

A high degree of automation and a repeatability in the µm range with docking forces higher than 3000 N guarantee maximum performance.

|

Towerless Probe Docking

|

Universal Prober Head Plate

|

|

|---|---|---|

|

for 8“ Prober

|

for 12“ Prober

|

for 12“ Prober

|

|

|

|

Turbodynamics' Docking Systems combine Automatic Test Equipment and Device Handling Systems. The patented P-DockⓇ and F-Dock clamping systems serve as a base and are tried and tested throughout the Semiconductor Industry.

The docking process takes place with a repeatable accuracy of less than 10 µm. High docking forces of up to several 1000 N per unit at shortest Z-Stack distance and zero maintenance are further advantages of our system.

Customers benefit from safety, repeatability and operator-friendliness, combined with highest precision. The systems are compatible with all common types of Handlers, Probers and Testers.

|

P-DockⓇ

|

F-Dock

|

|---|---|

|

|

Turbodynamics Technologies is a leading company involved in system integration and hard docking for the semiconductor business. An intense focus on docking technology has made Turbodynamics Technologies a trustworthy solution provider for handler/tester as well as prober/tester configurations in the semiconductor industry.