Non-Destructive TGV Laser Modification Inspection System

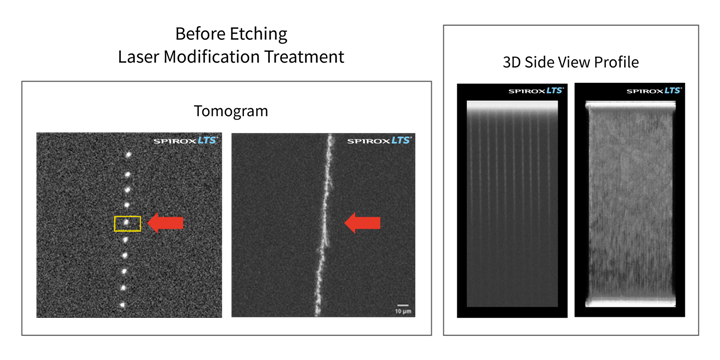

Tomogram of Laser Modification for Superior Pre-Etching Quality Assessment & Precision Control for Success!

PRODUCT DESCRIPTION

-

Exclusive Patented SpiroxLTS Technology

Advanced non-linear optical measurement with SpiroxLTS Technology for the improvement of the laser modification to best match the glass processing. -

No Destruction on Sample

Non-destructive inspection with SpiroxLTS enables precise control of laser modification performance, significantly reducing process costs and optimizing production conditions!

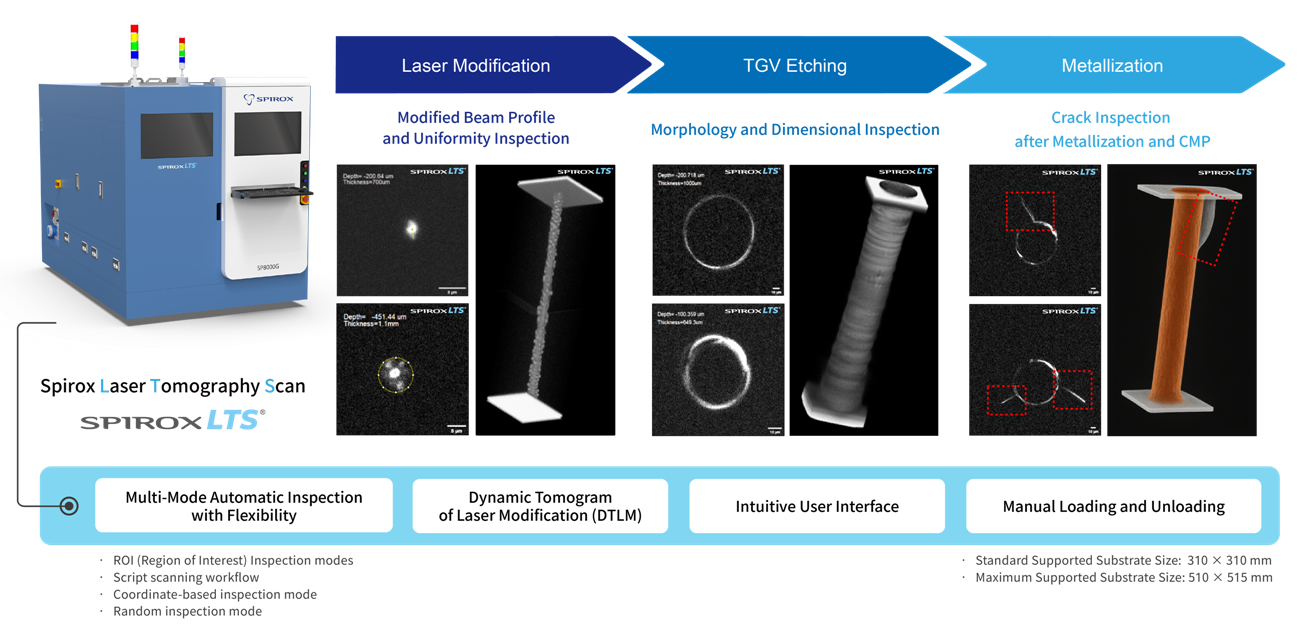

TGV Manufacturing Process Optimization: Key Role in Process Parameter Optimization

Laser Modification

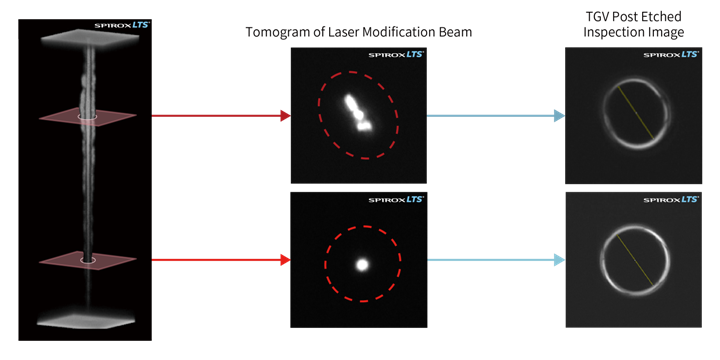

Laser Modification Impact on Post Etched TGV!

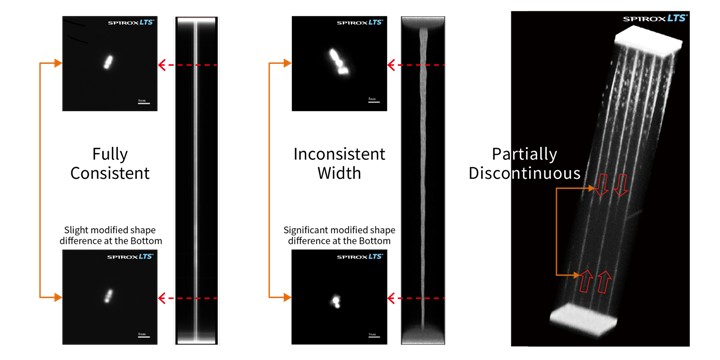

3D Tomogram : Uniformity and Continuity of Laser Modification

Dynamic Tomogram of Laser Modification

It’s able to observe Laser modification variations along the vertical depth changes.

Tracking Function of Dynamic Tomogram of Laser Modification

▯ : Focus Area ● : Observation Center ⬯ : Criteria Mask

![]()

TGV Etching

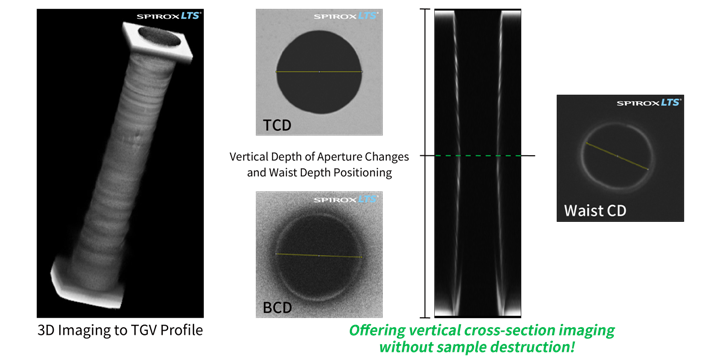

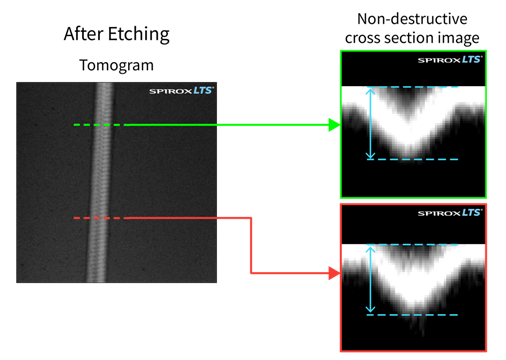

TGV Dimension Measurement

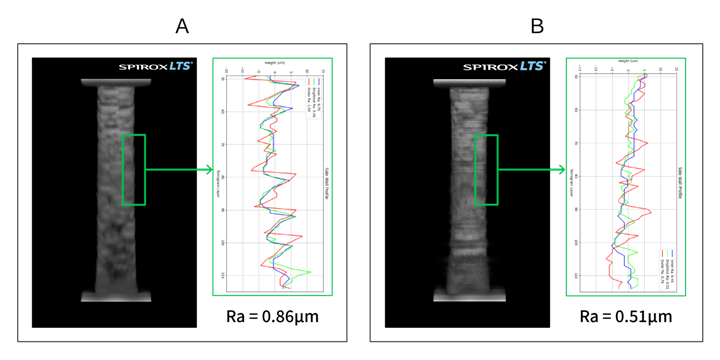

Roughness Calculation after Via Etching

It’s able to observe the difference of A & B by 3D profile image; Adopt Z axis resolution with precise level and inspection of micro area, the roughness could be calculated.

Metallization

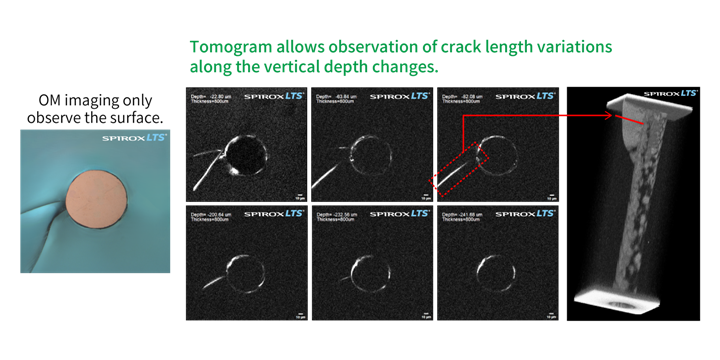

Crack Inspection after TGV Metallization and CMP

CPO & MORE APPLICATIONS

Co-Packaged Optics (CPO) Applications

Cavity in CPO Applications

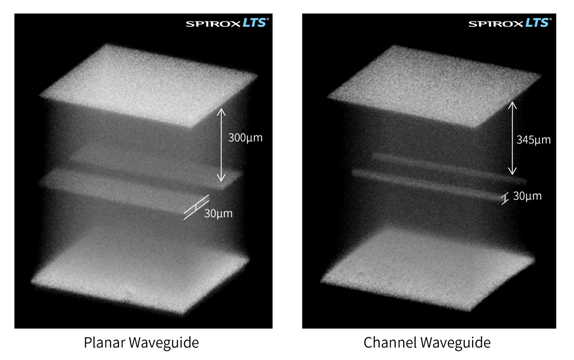

Glass Optical Waveguide in CPO Applications

It’s able to inspect the waveguide structure made by laser modification in the glass, and observe its profile with 3D image!

Dicing Lane Inspection

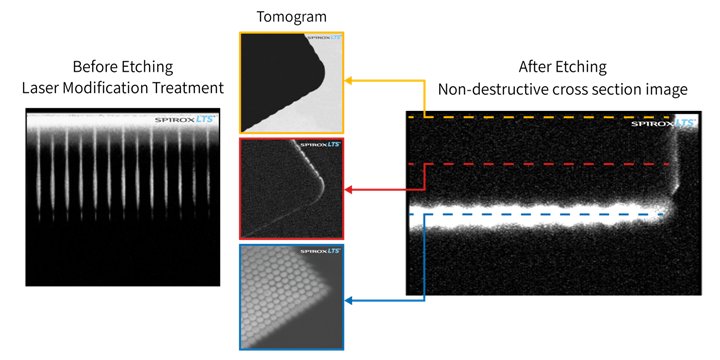

Laser Modification: Dicing Lane

After Etching: Dicing Lane Inspection

FEATURES

ADVANTAGES

The only technology for inspecting laser modification continuity and uniformity, providing early prediction of etched perforation outcomes after laser modification.

Tomogram of laser modification enables rapid adjustment of laser parameters and optimization of optical path design, significantly saving process development time.

Offering a more efficient, direct, and concrete inspection method without destruction.

Identify the waist position, critical dimensions, roundness, roughness, and the impact area, length, and depth of cracks after metallization.

FUNCTION DESCRIPTION

Significantly shortens development time and effectively reduces R&D costs. Precisely select laser source and glass material to ensure that TGV laser modification and through-via etching meet manufacturing quality specifications.

Monitor laser modification quality before etching, providing real-time prediction on whether etching is necessary, avoiding blind etching from past practices and preventing unnecessary cost waste.

Monitor TGV quality, reduce product defects, increase output, and prevent the batch costs associated with ineffective yield.

PRODUCT SPECIFICATIONS

| Item | Content |

|---|---|

| Model Number | SP8000G |

| Model Name | Non-Destructive Laser Modification Inspection System |

| Key Optical Technology | Patented SpiroxLTS Non-linear Optical Inspection (Application wavelength 1200 - 1800 nm) |

| Applicable Substrate Size |

Standard: 310 mm x 310 mm Maximum: 510 mm x 515 mm |

| Measurement Items |

Tomogram of Laser Modification, 3D Tomogram of Laser Modification, Dynamic Tomogram of Laser Modification; TGV Aperture Size and Roundness Measurement, TGV Waist Depth Positioning, TGV 3D Profile Image, TGV Cross Section Analysis, TGV Roughness Calculation; Crack Inspection after TGV Metallization and CMP |

| FOV / Measurement Time |

FOV 400 µm x 400 µm @ 20x objective magnification; 3.5 seconds / frame (Scanning resolution: 512 x 512 pixels);100 frames ≒ 6 minutes |

| Inspection Modes | Micro-area imaging, sub-region automatic measurement, coordinate-based automatic measurement, random automatic measurement, script scanning process. |

| Measurement Resolution |

Image Minimum Resolution 0.5 µm |

| Motion Resolution | X-Y axis Motion Resolution 0.1 µm, Z axis Motion Resolution 0.1 µm |

| Load & Unload |

Standard: Manual (Reserve space for EFEM upgrade) Maximum: Manual |

| Equipment Dimension / Weight |

Standard: Length 2.375 m x Width 1.780 m x Height 1.900 m Weight 2700 kg (Tentative) Maximum: Length 2.600 m x Width 1.600 m x Height 1.900 m Weight 3500 kg (Tentative) |

| Electrical Specification |

220 V 60 Hz AC 4400 W (Tentative) |