Non-Destructive Inspection System for SiC Crystal Killer-Defects

PRODUCT DESCRIPTION

The Best Substitution for KOH Etching Method!

FEATURES

ADVANTAGES

FUNCTION DESCRIPTION

- Low-cost DOE (Design Of Experiment)

- 100% inspection on extracted substrates out of one ingot for detailed ingot level quality analysis

- Enable effective tracking and analyzing ingots made by different batch or furnace

PRODUCT SPECIFICATIONS

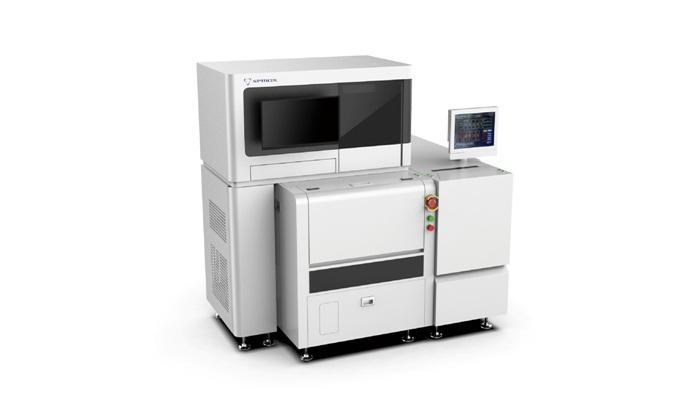

| Model Number | SP3055A | |

|---|---|---|

| Model Name | JadeSiC-NK, non-destructive inspection system for SiC killer defects (BPD/TSD/MP/SF), the best substitution for KOH etching method. | |

| SiC Substrate / EPI Wafer Size |

2” 4” 6” 8” | |

| Wafer Thickness | 300 μm - 550 μm | |

| Chuck | XY Stage Repeatability : 0.1 μm | |

| Inspection Items | Whole Wafer Defect Scan (MicroPipe, BPD, TED, TSD, SF, etc.) | |

| Whole Wafer Defect Scan | Estimated Inspection Time |

1 hr @4”wafer |

| Lateral Resolution | 1 μm | |

| Analysis |

MicroPipe Density (MPD) BPD/TED/TSD Density Stacking Fault Area Percentage Wafer Yield Tri-angle and Carrot** |

|

| MicroArea 3D Scan (optional) | Field of View |

400 μm x 400 μm |

| Scanning Zoom |

Yes ( 1x - 10x ) |

|

| Scan Resolution |

Up to 1024 x 1024 |

|

| Lateral Resolution |

0.4 μm |

|

| Axial Resolution |

0.25 μm |

|

| Min. Increment of Z stage |

0.02 μm |

|

| Wide Field Module Camera |

Color Camera |

|